Files available at: https://www.thingiverse.com/thing:4606129

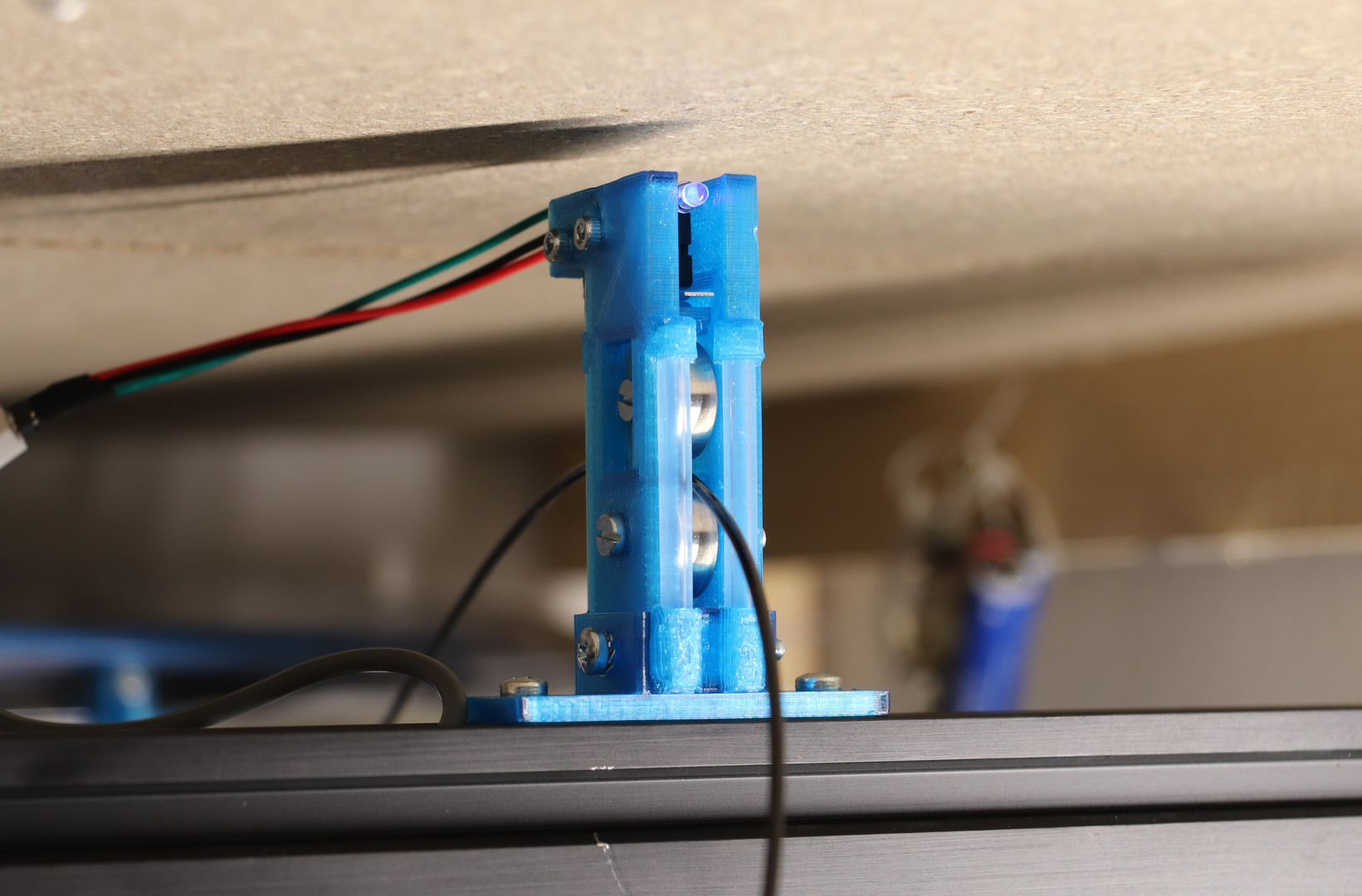

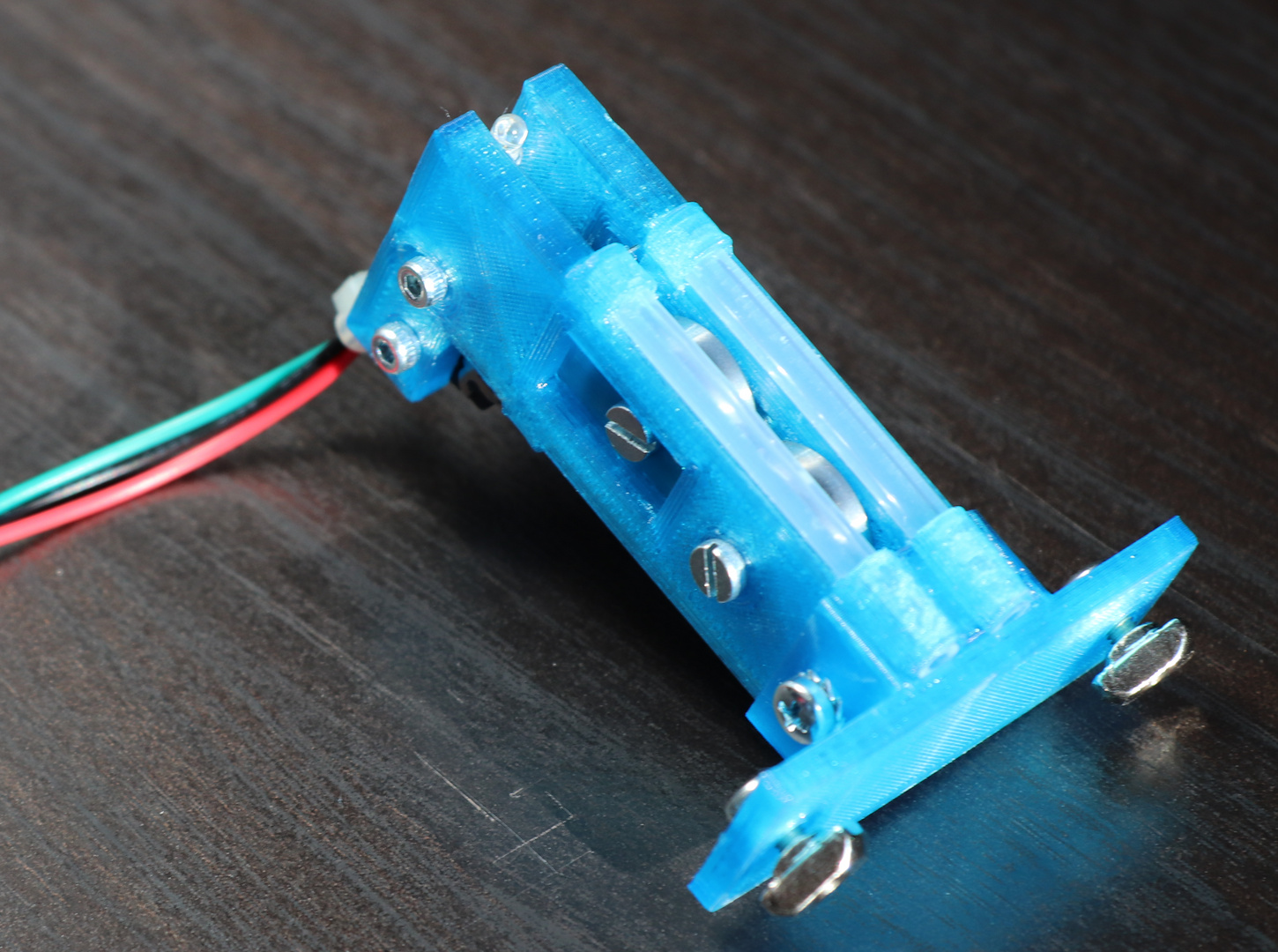

The filament runout sensor that was supplied with my FDM printer had problems with certain filament types. Very soft and wobbly filament couldn’t be inserted and sticky filament would bind hard enough to cause skipping of the feeder and thus result in printing issues. Also I moved the spool from the top of the printer to behind the printer which meant that I now needed a way to guide the filament around the top to the back. The idea was to combine both tasks, guiding and sensing, into one contraption. The result is this:

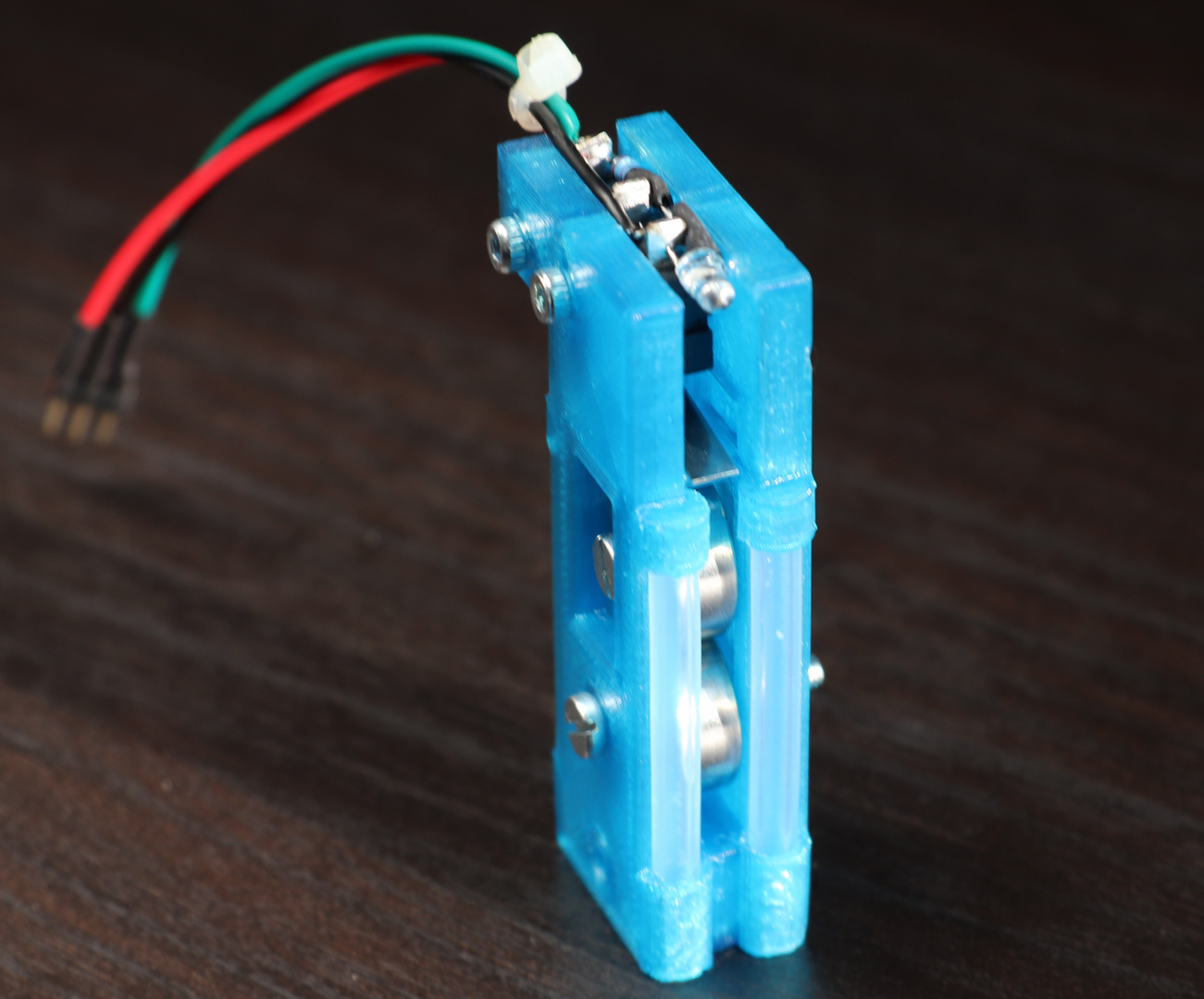

The filament is confined between two ball bearings, of which the upper one can move vertically and actuates a microswitch. The microswitch is adjustable in its position and I calibrated it so that it activates when the bearing surfaces are >1.4mm apart and disengages below 1mm to sense filament runout.

Sideways guidance, if needed at all, is provided by four PTFE tubings. The sideway forces are very minimal and the contact point between filament and the PTFE tube is tiny. The remaining friction is negligible. Also, it looks futuristic. 😀

At first sight it might seem a good idea to get rid of the side guides and instead have ridges on the outer sides of the bearings to keep the filament horizontally confined. But that would require that the vertical travel of the sensing bearing is limited to less than the filament diameter (i.e <1.75mm). In contrast, having more vertical travel is beneficial for very stiff materials because it can more easily accommodate for the high bending radius and thus is easier on the filament.

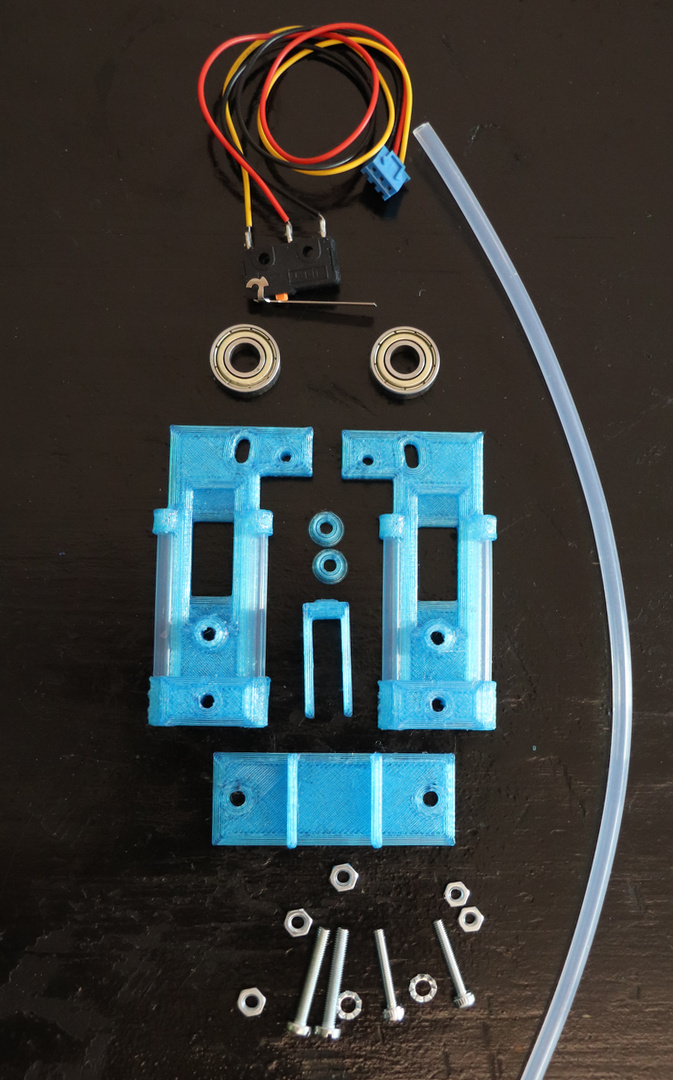

What you need:

- 1x micro switch (the big type: 6.5 x 19.5 x 9.5mm)

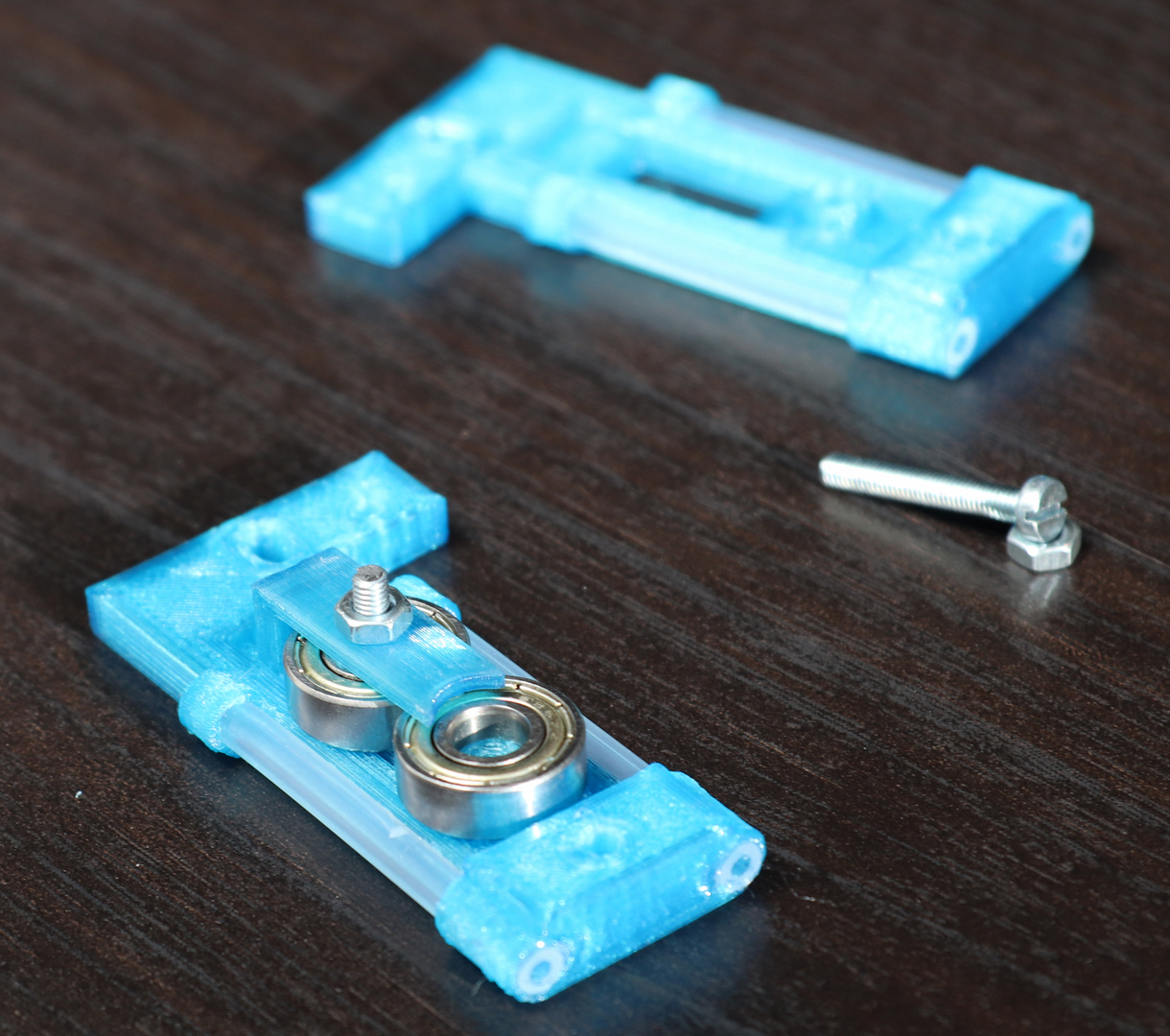

- 2x bearing 696ZZ

- 2x M3 screw 20mm + nut (for bearings)

- 1x M3 screw 25mm + nut (for base)

- 2x M2.5 screw 20mm + nut (for micro switch)

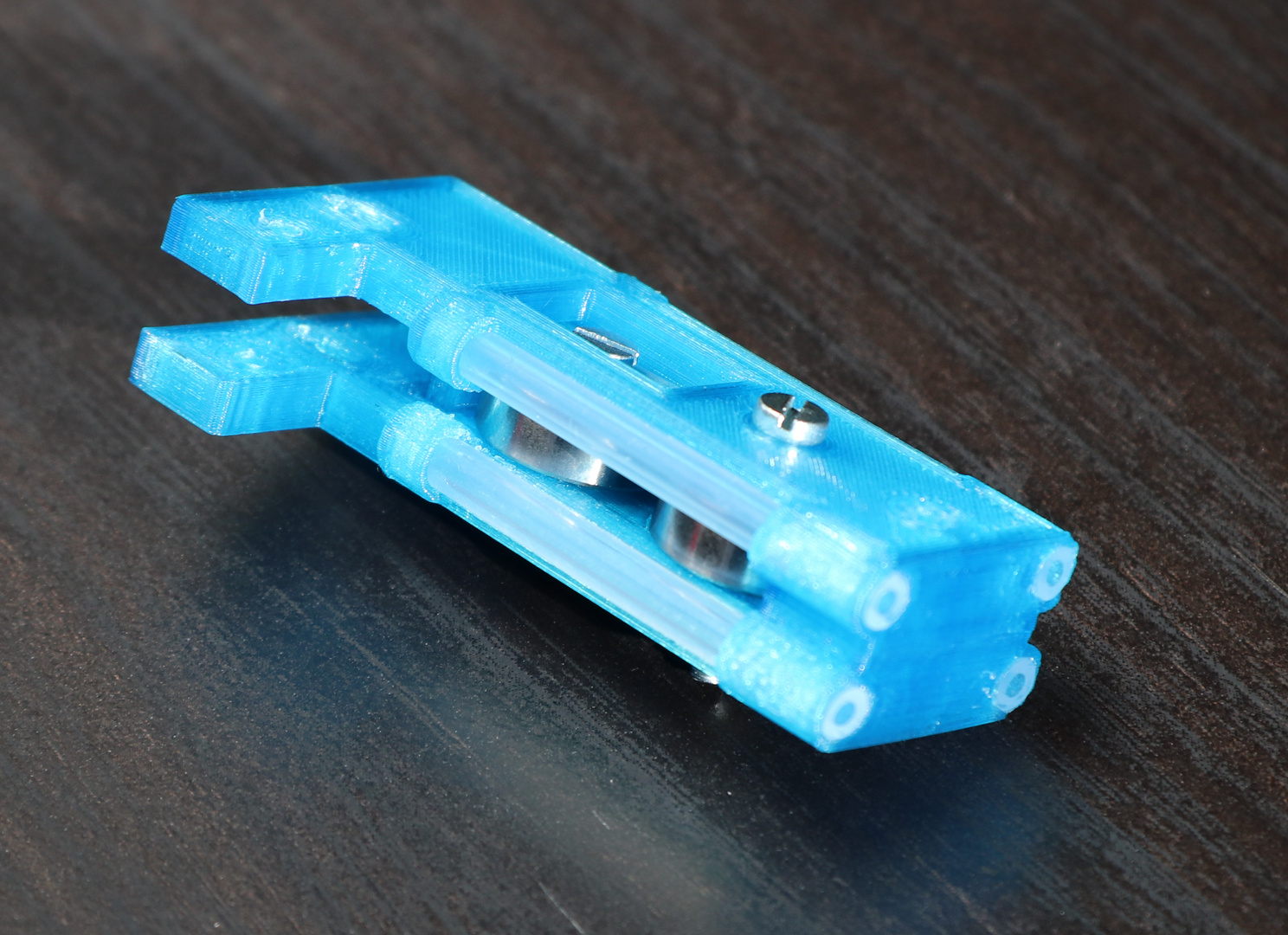

- 4x PTFE tubing, 4mm diameter, 43mm length

Printed parts:

- 2x spacer

- 1x slider

- 1x side

- 1x side (mirrored)

- 1x bottom

Files available at: https://www.thingiverse.com/thing:4606129

How to build:

Materials

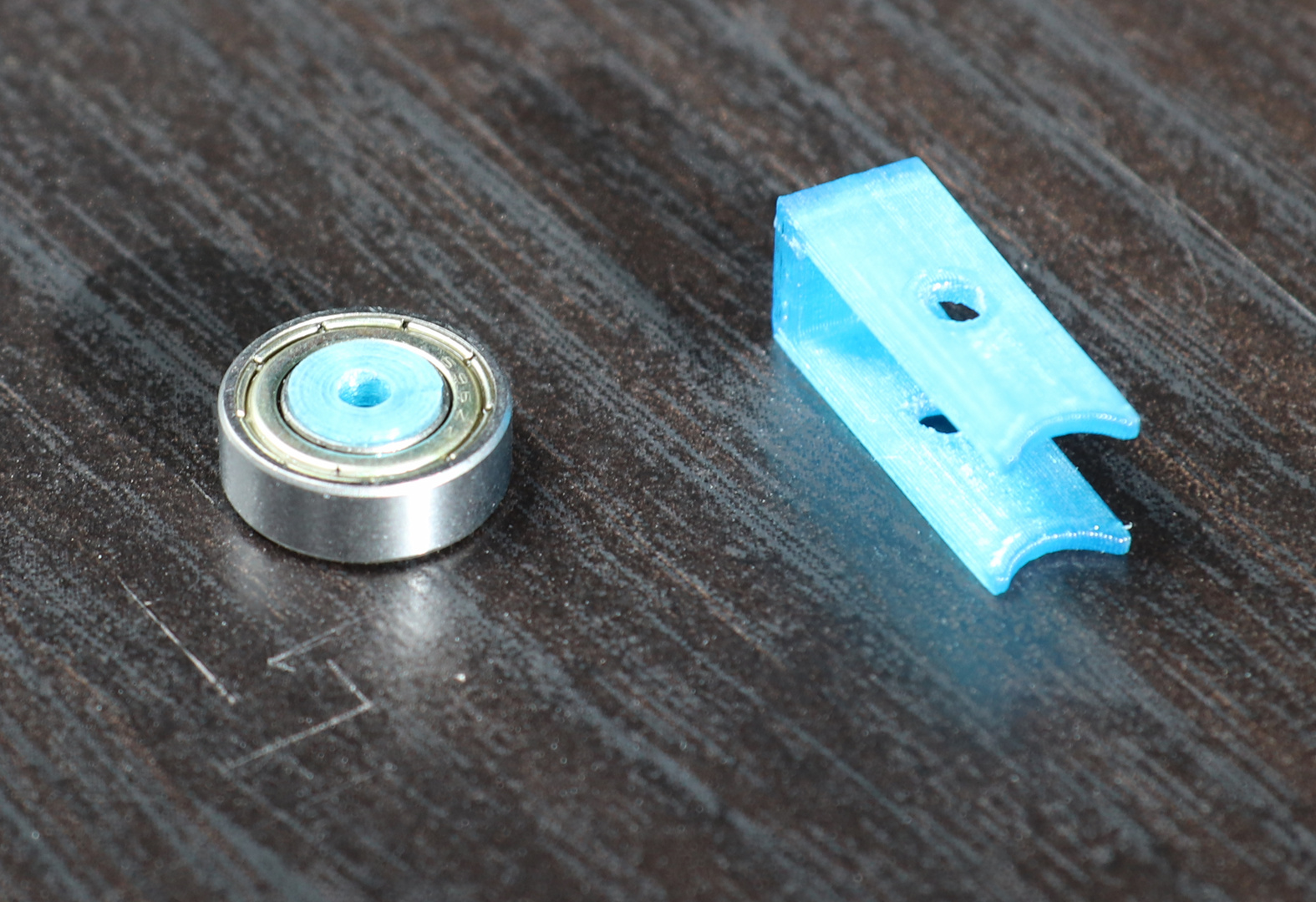

Step 1: Insert spacers into first bearing. Make sure the rim of the spacer is actually 0.5mm thick.

Step 2: Attach bearing with spacers to the slider.

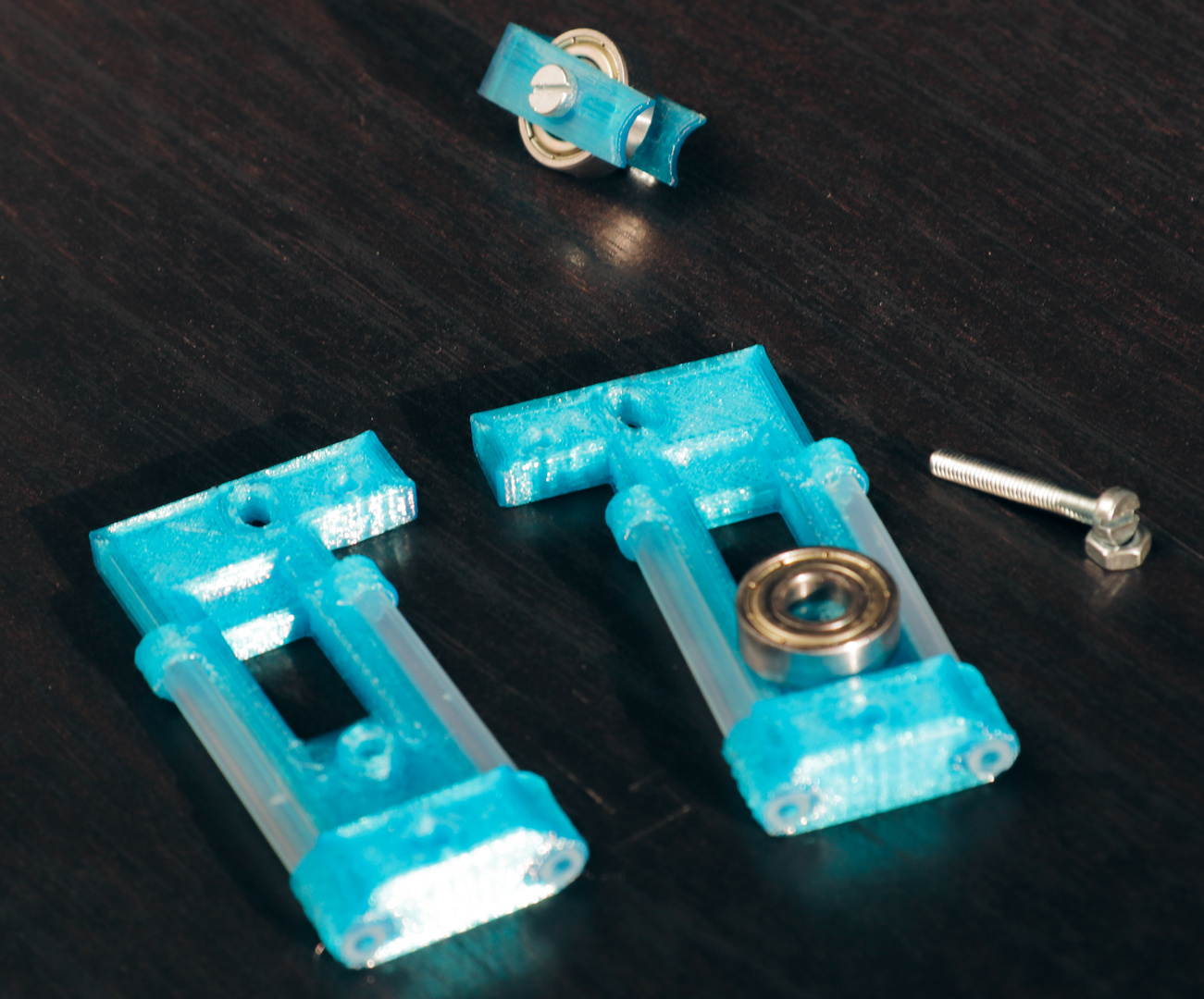

Step 3: Inset PTFE tubing into the sides, place second bearing.

Step 4: Place the slicer

Step 5: Attach the second side and secure it with a screw.

Step 6: Inset microswitch using the M2.5 bolts. Adust its height (front screw can slide up and down).

Step 7: Attach bottom.

Excuse the wild mix of screws. That’s what I had at hand.